What Brian Stall says about Jingdiao High-Speed Mills

As the Gosiger 3D Application Engineer, I spent over 500 machining hours during an 8-week period evaluating the Jingdiao 5-axis mill at our Dayton headquarters. The Jingdiao engineers supported me during the entire process. If they couldn't answer a question, they would have it the next day. I was extremely impressed with their technical skills and response time.

I cut multiple samples on the Jingdiao GRA400 5-axis machining center including micron-level parts with mirror finishes. Parts were programmed both with 3rd party CAM software and Jingdiao's own Surfmill CAM software. I found Surfmill to be intuitive, and powerful with many standard features. Because of the machine's rigid bridge-style construction, thermal stability, 3D tool compensation, and on-machine measurement, the Jingdiao can cut high-precision micron-level parts.

We were so impressed with the machine and their people that we are now their exclusive full-service dealer in Washington, California, Michigan (east and west), Indiana, Pennsylvania, Florida and Ohio.

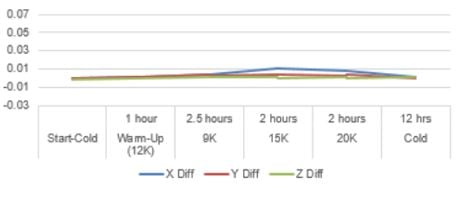

The below graph shows the stability of the Jingdiao machining center which results in high-precision machining.