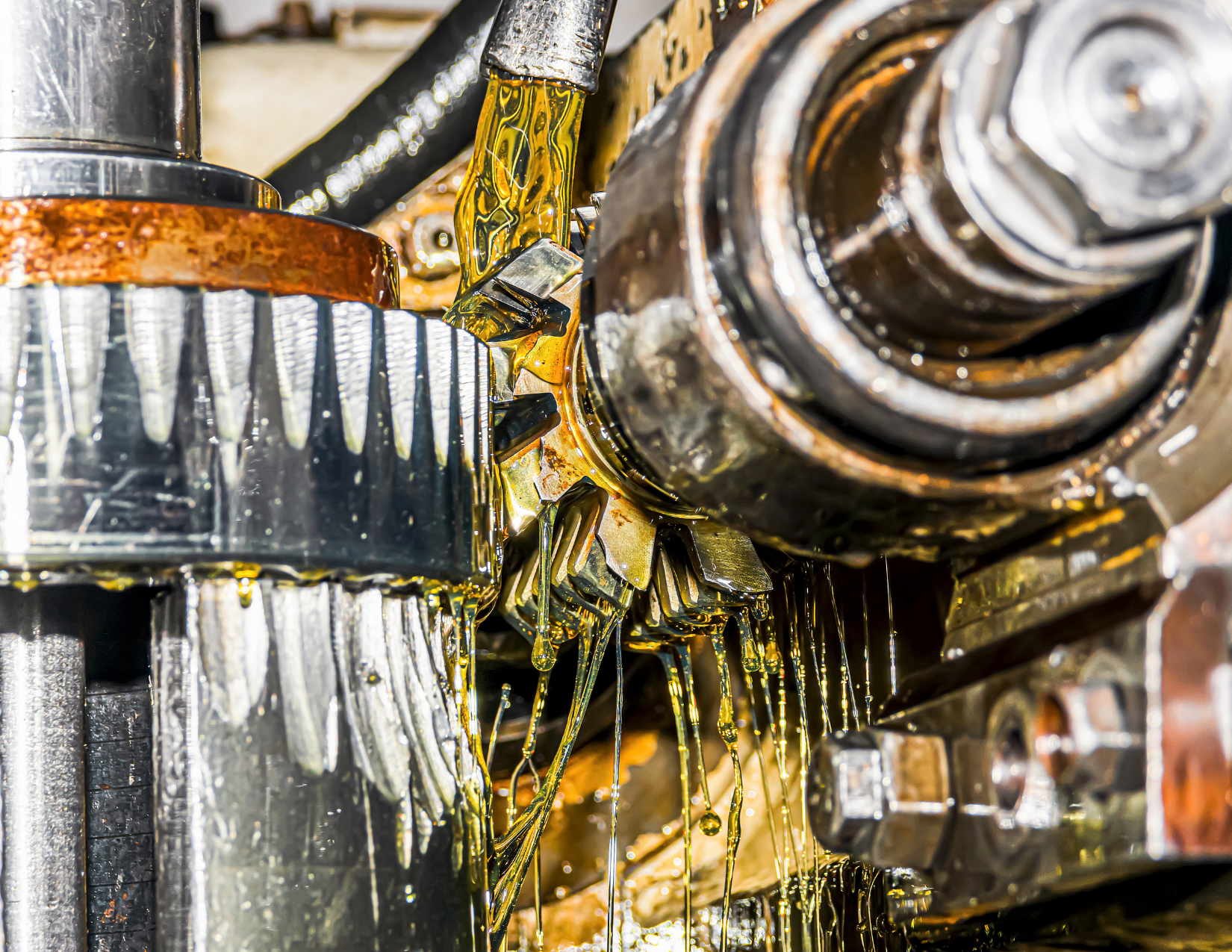

The manufacturing process isn’t just making and shipping parts. Measurement tolerances are only the first half of the requirements when preparing to ship a part to your customers. In today’s manufacturing world, most items must be cleaned and coated with some form of rust prevention to protect the parts.

How do you wash your parts and how much is it costing you? There are many factors to consider when setting up an environment for cleaning your parts and, based on your needs, you may be using an inefficient system that is wasting time and money.

Parts washing systems can be broken down into two main categories: water-based (or aqueous) and solvent-based. Aqueous systems are best utilized for parts manufactured in water-based coolant and containing water-soluble cutting lubricants. Solvent-based systems are the best for removing oil-based cutting fluids.

.png?width=1650&name=IMMERSION_WASHER%20(1).png)

Immersion washers feature dunk tanks for the wash-rinse-dry cycle and can also exist as rotary systems. Heated air is most commonly used to dry the washed parts.

Spray washers offer a simple wash-rinse-dry cycle on an inline or rotary conveyor and rely on heated forced air for drying.

Conventional vapor degreasers are “open atmosphere” systems in which parts are suspended above a heated basin filled with solvent and cleaned by the evaporating solvent.

Manual degreasers are stations where operators individually clean each part in a solvent, which results in wasted time and effort from the operators.

Vacuum parts washers are fully self-contained, airtight cleaning systems that keep solvent vapors from leaking into the plant and recycle solvent, cutting costs.

Each system has its applications and associated cost. To determine which parts washing solution best fits your plant, you need to consider multiple factors, including soil type, part geometry, desired cleanliness targets and production volume.

Obviously, the end goal is to effectively clean parts made in oil or water, but what parts-washing chemistry works best? A good first step is to examine the cutting fluid used in your machining processes. Typically, water-based coolant is used in machining centers, grinders, and conventional lathes. Conversely, Swiss and multi-spindle lathes, forming/stamping machines, and other grinding/honing machines tend to use oil. If you’re using oil in your manufacturing process, a solvent-based washer might be a better choice.

The reason water and oil do not mix is that water is polarized and oil is not. Due to this characteristic, water is not fit for removing oil-based lubricants from a surface without the addition of cleaning agents or detergents. These agents act by capturing the oil in bubbles, which will be skimmed or carried away in the rinse cycle. The type of agent you use will vary based on your part materials and other factors, so you may end up needing multiple chemistries for different cycles.

A solvent-based solution will remove oil from your parts much more effectively. However, most solvents contain hazardous chemicals that require special precautions, as they can atomize and mix with the air during the cleaning process, presenting a dangerous work environment. There are “greener” alternatives, but these solvents can be more costly.

Modified alcohol is a water-free solvent with excellent cleaning power, containing both polar and non-polar properties, allowing it to clean parts made with oils or water-based coolants. KYZEN Metalnox M6386 is a non-hazardous, biodegradable organic solvent that is RoHS compliant, CFC-free, Halogen-free and non-flammable, making it a greener option than most other solvents.

Soil buildup and chip fines in complex parts can be an obstacle for traditional parts washing systems. Blind holes and internal grooves, for instance, are difficult for a spray washer to completely clean in a bulk load. Washing complex parts in bulk will leave parts in the center basket wet if they are dried with hot air. In either of these scenarios, an operator is usually required to finish the job by spraying each individual piece with an air hose. At this point, you’ve lost time and money trying to meet cleanliness specifications on each part, so you need to find the best way to wash a challenging part.

Some examples of challenging parts include parts with:

Intersecting holes and internal grooves and recesses

Small, blind or tapped holes or parts of an assembly

Die-cast parts or long, tubular parts with compound bends

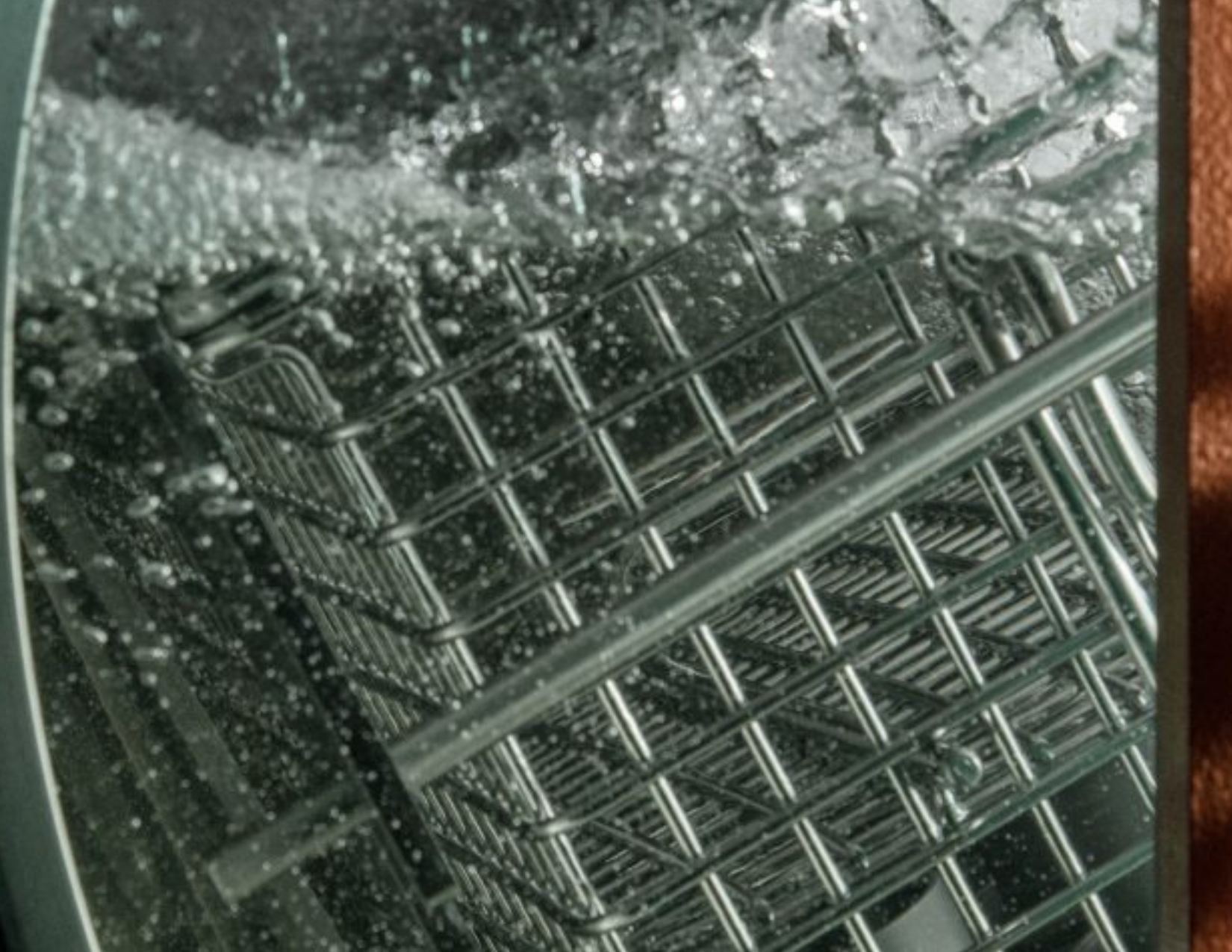

The iFP line of parts washers utilizes a vacuum chamber in combination with ultrasonics to generate a superior cleaning environment. Solvent in a vacuum eliminates bubbles, which create voids that trap and protect soils. Ultrasonics utilizes vibrations in the solution which break up the tougher soils trapped in blind holes and internal crevices. The vapor cycle heats the parts and removes the remainder of the soils. At this point in the cycle, if requested by the user, rust prevention is mixed with the solvent and applied to the parts. The parts are then dried via vacuum.

The iFP process ensures a fully cleaned and fully dried batch of parts every cycle. We offer custom basket configurations as well, so if you have a high-mix batch of parts, we can accommodate it in a single load. If your parts require separation, our baskets can handle that as well. With a cycle time of 9-15 minutes, iFP machines are a smart investment for a clean and green parts washing system.

With iFP, you can achieve customer cleanliness specifications in a number of applications with a single cycle with no need for additional runs or manual rework.

Fumes from evaporated oils are hazardous, resulting in EPA regulations on chemicals in the workplace. This led to some companies switching to aqueous systems, which resulted in a need for multiple costly detergents to accommodate their parts. Others chose to switch chemicals to meet the new standards. Finding “green” chemicals to replace these oils can be costly, and you’re still introducing vaporized oil into your plant’s environment, so how do we meet EPA standards in a cost-effective way?

That’s where vacuum chamber parts washers come into play. Since vacuum parts washers are standalone, self-contained, and air-tight, they eliminate concern brought forth by vapor degreasers. iFP parts washers utilize KYZEN Metalnox M6386, a modified alcohol, in order to be more environmentally friendly and cost-effective. iFP and KYZEN make a great team that can eliminate the use of water and consumable chemistry in your parts-washing process, eliminate the need for manual rework, and maintain RoHS and REACH compliance.

That’s where vacuum chamber parts washers come into play. Since vacuum parts washers are standalone, self-contained, and air-tight, they eliminate concern brought forth by vapor degreasers. iFP parts washers utilize KYZEN Metalnox M6386, a modified alcohol, in order to be more environmentally friendly and cost-effective. iFP and KYZEN make a great team that can eliminate the use of water and consumable chemistry in your parts-washing process, eliminate the need for manual rework, and maintain RoHS and REACH compliance.

If water consumption is a concern for your company, utilizing solvent in an iFP system is the solution. iFP can recycle the KYZEN solvent so effectively as to use up one gallon of solvent per 10 gallons of removed oil. This can help you offset the cost of an aqueous system.

iFP offers all the following benefits and more:

If you want to revolutionize how you clean your parts or just have questions about iFP, have a chat with our inside sales team, and we’ll be happy to help!