Is There a Robot in Your Manufacturing Future?

It seems like the pressure on manufacturers just keeps building. The competition is coming at you from down the street, around the corner and across the water. Costs for qualified operators (if you can find them), health care, materials and energy keep rising, while customers demand higher quality, lower prices and faster delivery.

It seems like the pressure on manufacturers just keeps building. The competition is coming at you from down the street, around the corner and across the water. Costs for qualified operators (if you can find them), health care, materials and energy keep rising, while customers demand higher quality, lower prices and faster delivery.

For all of these reasons, manufacturing turns to factory automation to reduce time to market and labor costs. In fact, since 2009 expenditures for capital equipment rose 31% while private sector jobs grew only 1.4%.

Much of this capital equipment investment has been in faster, smarter, more capable CNC machine tools. However, to realize the best return on this investment, manufacturers must consider their entire production scheme – upstream and downstream of the CNC machining cycle. Fact is, loading and unloading parts and conveying them to the next phase of production can be the weakest link in an otherwise efficient manufacturing process.

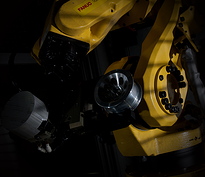

In many situations, the logical way to automate loading and unloading is by using industrial robots. At last count there were 213,000 such robots working in U.S. factories. Yet it’s estimated that only 10% of the U.S. manufacturers who could benefit from robotic factory automation are using them.

Are you one of them?

Gosiger Automation designs and builds custom factory automation systems that integrate CNC machines with robots and other peripherals to dramatically reduce labor costs and enable workers to be more productive. It all begins by applying Gosiger’s 90 plus years of machine tool experience to thoroughly analyze your unique requirements and recommend a solution that precisely fits your needs.

So bring your manufacturing productivity goals to Gosiger Automation today and see if robotic factory automation is the right choice for your operation.