5 Reasons the Nomura Swiss Style Lathe is Right for You

Posted by

Gosiger on Wed, Apr 17, 2013

Gosiger is pleased to compliment its broad line of CNC machine tools with the Nomura brand of Swiss-style turning machines. Nomura is a leading manufacturer of turning centers with more than 50 years of experience building precise, reliable CNC machines.

Gosiger is pleased to compliment its broad line of CNC machine tools with the Nomura brand of Swiss-style turning machines. Nomura is a leading manufacturer of turning centers with more than 50 years of experience building precise, reliable CNC machines.

Among the unique design and construction features of the Nomura machines are:

- Spindles made from SCM415 Chrome Molybdenum that are heat treated on the outside for durability while the inside is hardened to a different degree, thereby enhancing stability and strength.

- The guiding system design uses a linear guide with preloaded roller pads. This construction enables the headstock to move smoothly and accurately, while the sliding mechanism absorbs much of the harmonic vibrations caused by high-speed rotation of bar stock.

- To further reduce vibration, the main tool holder slide is guided by dovetailed slides that move on a thin film of oil.

- To achieve greater surface smoothness and flatness Nomura uses a 200-year old hand scraping technique called Kisage that produces an ultra-precise surface with sub-micron unevenness of less than 0.0001mm.

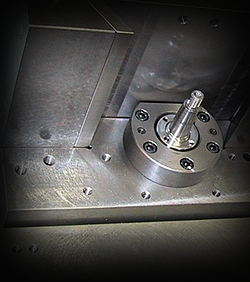

- A proprietary outboard tool pre-setter with a tool holder and 10X microscope simplifies accurate tool setting by adjusting the cutting edge in the X & Y axial direction, and the blade end for the Z-axis. The result is faster, more accurate tool setting than with typical Swiss-style lathes.

For more information contact Gosiger, Inc., the exclusive North American distributor for Nomura Swiss-style CNC turning centers.