Considering Medical Parts Machining? Ask Yourself These 7 Questions

It’s no secret that there are vast numbers of medical products being manufactured for a wide variety of applications. These products may be as simple as a hand-held instrument, as complex as a computer-based imaging device and as unique as a custom-fit prosthesis. One thing they all have in common is that they impact the lives and wellbeing of millions of people. Therefore the machining of the parts that make up these devices must be held to extremely high standards, including zero defects.

It’s no secret that there are vast numbers of medical products being manufactured for a wide variety of applications. These products may be as simple as a hand-held instrument, as complex as a computer-based imaging device and as unique as a custom-fit prosthesis. One thing they all have in common is that they impact the lives and wellbeing of millions of people. Therefore the machining of the parts that make up these devices must be held to extremely high standards, including zero defects.

Another commonality is that medical products companies typically contract with CNC machine shops to produce various parts, so there is a great opportunity for shops that would like to expand their business. As always, with opportunities come challenges, and breaking into the medical machining market is no exception.

With that in mind, here are 7 questions to ask yourself as you consider this opportunity:

- What kinds of medical machining are you best suited for? Some of the most common types are:

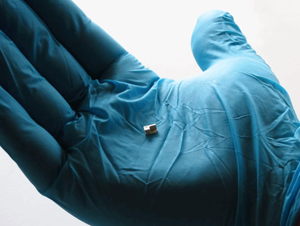

- Micromachining of tiny, highly-precise implants

- Custom machining of replacement joints, prosthetics and other items that must be adapted to an individual’s body

- High volume machining of turned parts like dental implants or injection needles

- Prototype machining of new medical products

- Producing small runs of large families of parts

- What certifications are required? Manufacturing most medical parts require following and carefully documenting procedures including providing part identification for traceability. Once you determine the kinds of medical machining services you wish to provide, you’ll need to determine and acquire the appropriate certifications.

- Do you have expertise with exotic materials? Many medical parts are made from titanium or sophisticated alloys. If you don’t have experience working with these types of materials, you’ll need the help of applications experts.

- Is your equipment capable? The demands of dealing with exotic materials, tight tolerances and zero-defects means that you must have CNC machines and peripherals designed for these tasks. Much like machining for the aerospace market, and depending on the nature of medical parts you plan to produce, you need to have equipment that will enable you to make the parts as accurately and efficiently as possible.

- Do you have multi-axis capabilities? Medical parts machining is a highly competitive business. Successful shops strive to complete machining operations on one machine with the fewest setups and fixtures. Horizontal Machining Centers (HMC), including those that provide true 5-axis machining, are often the best answer.

- Does your CNC machine control provide adequate documentation? The FDA (Food & Drug Administration) issues strict regulations for manufacturing medical devices. A recent development is a new FDA focus on auditing smaller shops that supply components to the OEMs. Therefore it’s a great advantage to have a CNC control, like the open format, PC-based Okuma OSP, that is well suited for documenting setup, quality control and adherence to standards.

- Do you have an equipment provider that understands the medical market? Gosiger specialists can help you select the right CNC machine tools and accessories, provide expert applications assistance, and call on years of experience dealing with exotic materials, appropriate cutting tools and much more. Plus, Gosiger can provide everything you need for medical parts machining including a wide range of multi-function machine tools, laser marking equipment, Swiss machines, chip and coolant management systems, bar loaders, pallet systems and robotic-based factory automation. All backed by industry-leading technical service and customer support. Contact Gosiger today for all the facts.

Thanks to Gosiger team members Derek Noe & Steve McDonald for their contributions to this article.