Tech Tip: Maintaining Through Tool Coolant Pins

For those who have through tool coolant delivery systems on their CNC machines, keeping the coolant pins clean and functioning, and replacing them as needed should be part of your planned preventative maintenance program. However, some shops forget about these small items and the result can be costly.

For those who have through tool coolant delivery systems on their CNC machines, keeping the coolant pins clean and functioning, and replacing them as needed should be part of your planned preventative maintenance program. However, some shops forget about these small items and the result can be costly.

As indicated in this photo, some of these pins have a nylon washer and O-ring that keep coolant out of the thrust bearings. If these components wear out and are not replaced, coolant will find its way into the thrust bearings and wash away the grease and protective material inside the bearings. This causes increased friction that leads to excessive wear and damage to the spindle.

Because the coolant pin washer and O-ring are items that wear normally and need replacing as part of routine machine maintenance, damage to the spindle caused by lack of coolant pin maintenance voids any existing warranty on the spindle. Therefore failure to perform this simple, routine maintenance procedure creates additional repair cost and lost production time.

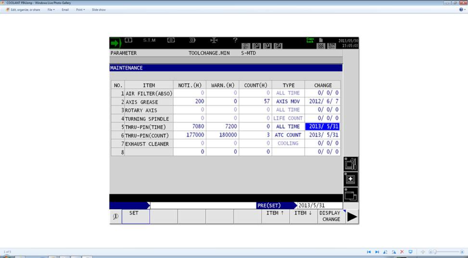

Okuma machines equipped with the P200 control have a built-in maintenance screen that counts total machine time and tool changes to help keep track of coolant pin life. The operator’s manual for the machine explains how to set the date and activate the screen.

This is just another example of the importance of having a consistent, planned preventative maintenance program in your shop. Such a program performed by experienced, knowledgeable professionals can greatly benefit any manufacturing concern. That’s why Gosiger offers a comprehensive preventative maintenance program tailored to each customer’s specific needs. With over 90 years of machine tool experience, no one is better equipped to provide the service you need. Contact Gosiger today for more information.

|

|