Gosiger Automation Video Demonstrates Improved Loading & Unloading Process

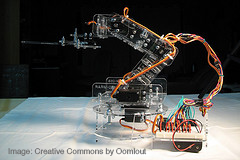

It’s no secret that using robots to handle large, heavy, unwieldy parts reduces production time and eliminates many worker safety issues. However even a basic loading and unloading scenario, like the one in this video, requires much more than simply placing a robot arm in front of a machine tool. Gosiger Automation specializes in thinking through the entire manufacturing process to integrate all of the components necessary to achieve optimum productivity.

It’s no secret that using robots to handle large, heavy, unwieldy parts reduces production time and eliminates many worker safety issues. However even a basic loading and unloading scenario, like the one in this video, requires much more than simply placing a robot arm in front of a machine tool. Gosiger Automation specializes in thinking through the entire manufacturing process to integrate all of the components necessary to achieve optimum productivity.

In this case, the machining of these large wheels required a Fanuc R-2000 iB Robot that uses its on-board vision system to properly locate and relocate the parts throughout the machining cycle, along with two conveyor belts to move the parts into and out of the process. Gosiger Automation programmers tied the entire process together into a seamless operation.

View the video below and contact Gosiger Automation for more details.