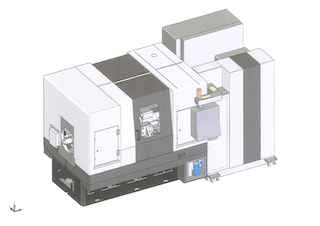

Gosiger High Volume Introduces: The Shimada Hybrid CNC Multi-Spindle Bar Machine

THE RIGHT MACHINE FOR THE RIGHT PRICE

THE RIGHT MACHINE FOR THE RIGHT PRICE

In the past, manufacturers chose between CAM actuated automatics and full CNC multi-spindle machines. The cost of a CAM automatic has increased dramatically over time while the challenges of set up, changeovers and finding skilled labor remains. The CNC versions are very capable but come with a very high price tag. Many parts do not require all of the sophistication of these machines. This is the fit of the new Shimada design. The ISM B27 has many of the advantages of the full CNC machines but at a price that can be justified for the kind of work it will run. It is a well-balanced combination of multi-spindle technology and renowned Japanese accuracy and reliability.

THE TECHNOLOGY

The new machine has (6) integrated spindle motors that allow independent control of RPM by program. Capabilities include spindle stopping, C-axis positioning as well as constant surface footage. The initial hydraulic slides allow for simple roughing operations while the CNC slides provide smooth and accurate single point finishing. The machine is equipped with the Fanuc 30i control and servo motor package for excellent reliability and performance. Numerous attachments are available to further extend the B27’s capabilities.

Gosiger High Volume is a subsidiary of Gosiger Holdings, Inc. specializing in providing solutions to high volume parts manufacturers in North America. The division’s additional capabilities include Nomura Swiss, BTB Transfer, Sinico double end-working machines, Shimada multi-spindle chuckers and iFP vacuum chamber parts washers. Gosiger started in the high volume field by engineering solutions around the Euroturn multi-spindle automatic and currently boasts over 350 machine installations nation-wide. Shimada is a family owned and operated company that has manufactured all of their machines in Toyokawa, Japan since 1947. The company produces multi-spindle bar and chucker equipment as well as an innovative line of single and twin spindle machines focused on shorter cycle times.

Established in 1922, Gosiger prides itself in offering some of the most innovative manufacturing technologies and solutions available today. Beyond high-performance CNC machine tools from Okuma and Hardinge, Gosiger solutions include factory automation, turnkey project engineering and 24/7 product support. Gosiger consultants and engineers expertly guide manufacturers to the right machines needed to make parts effectively and profitably. They help solve production issues and business problems using our collective expertise and robust technical solutions. Gosiger features 15 strategically located facilities and is headquartered in Dayton, Ohio, where second and third generation family owners still operate the company.