Impressive Video Demonstrates High Feed Rate Milling Technique

Posted by

Gosiger on Fri, Aug 08, 2014

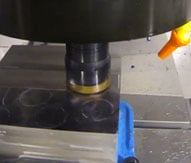

Milling this complex part from pre-hardened 4140 steel (36 Rc) required a combination of a machine tool capable of both high speeds and the ability to precisely control machine movements, an assortment of high-performance cutting tools, and the right CAM software. In this video, the cast of characters includes an Okuma Genos M560V vertical machining center, Sandvik-Coromant tooling and Esprit ProfitMilling CAM software.

Milling this complex part from pre-hardened 4140 steel (36 Rc) required a combination of a machine tool capable of both high speeds and the ability to precisely control machine movements, an assortment of high-performance cutting tools, and the right CAM software. In this video, the cast of characters includes an Okuma Genos M560V vertical machining center, Sandvik-Coromant tooling and Esprit ProfitMilling CAM software.

The 10-minute video takes the viewer through the various steps required to produce this complex part:

- Using the roll-in method reduces tool wear as it cuts thin-to-thick, while the cut loop pattern efficiently removes the remains

- The next phase uses ProfitMilling @ 12K RPM and 700 IPM, with 1400 IPM linking

- Channel cutting commences @ 7K RPM and 323 IPM continuous ramping

- Next is a helical ramp @ 5240 RPM and 100 IPM at a 2º ramp angle

- ProfitMilling at this step enables 10.5K RPM and 200 IPM with 820 IPM linking

- Chamfering concludes the operation @ 12K RPM and 200 IPM

Gosiger’s Senior 3-D Applications Engineer, Brian Stall, prepared this demo. Contact Gosiger for more information and demonstrations of high-efficiency machining.