According to survey data released by Gardner Business Media, American manufacturers have rebounded from the Great Recession. In fact, the Index of Durable Goods showed that production of durable goods is at an all-time high.

According to survey data released by Gardner Business Media, American manufacturers have rebounded from the Great Recession. In fact, the Index of Durable Goods showed that production of durable goods is at an all-time high.

According to survey data released by Gardner Business Media, American manufacturers have rebounded from the Great Recession. In fact, the Index of Durable Goods showed that production of durable goods is at an all-time high.

According to survey data released by Gardner Business Media, American manufacturers have rebounded from the Great Recession. In fact, the Index of Durable Goods showed that production of durable goods is at an all-time high.

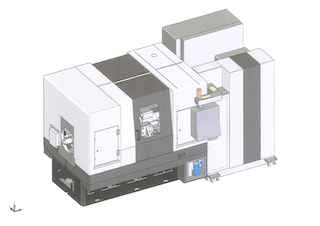

Thanks to a new programming option called Turn-Cut, users of Okuma Horizontal Machining Centers (HMC) can now avoid buying expensive special purpose machines, tooling, fixtures and other add-ons to perform turning operations on large, unbalanced parts. With it you can create bores and diameters including circular and angular features. The system is especially useful for working on valves and manifold-type parts.

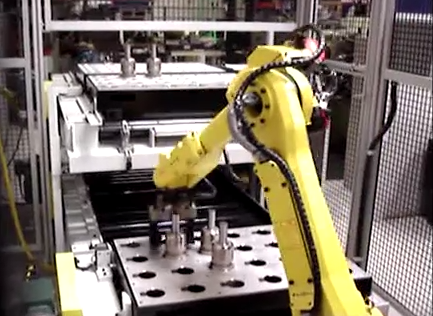

In this Gosiger produced video, a Fanuc M-16iB robot unloads and stacks precision aluminum parts. The work cell is designed for long periods of unattended operation of the Okuma sub-spindle lathe that is fed 12’ bar stock by an automatic, magazine bar feeder. The Fanuc robot gripper carefully unloads the parts because the robot is programmed to apply the optimum amount of pressure. This ensures that the highly precise aluminum parts will not be damaged or distorted when removed and placed in the outgoing conveyor.

In this Gosiger produced video, a Fanuc M-16iB robot unloads and stacks precision aluminum parts. The work cell is designed for long periods of unattended operation of the Okuma sub-spindle lathe that is fed 12’ bar stock by an automatic, magazine bar feeder. The Fanuc robot gripper carefully unloads the parts because the robot is programmed to apply the optimum amount of pressure. This ensures that the highly precise aluminum parts will not be damaged or distorted when removed and placed in the outgoing conveyor.

We’re all looking forward to the promise of another good year for manufacturing in 2014 and, although it may seem far away, we’re also looking forward to IMTS 2014. Early indications are that a record number of exhibitors and visitors will grace the halls of McCormick place next September 8 – 13. Certainly there will be exciting new technologies and sharing of information that will help everyone from the smallest CNC machine shop to the largest mega-manufacturers advance their operations. Here are a few other highlights according to information released by The Association for Manufacturing Technology (AMT).

The science of ergonomics involves designing and arranging things so that people can use them as efficiently and easily as possible. When ergonomics is applied to CNC machining the primary focus is on improving productivity and safeguarding the machine operators.

Hardinge, Inc. presents a 2-day event for CNC machine shop personnel who want to see the latest machine tool technologies from Hardinge, Bridgeport, Kellenberger, Jones & Shipman, and Usach. Along with these industry-leading turning machines, machining centers, grinders and workholding products, 40 Hardinge Technology Partners, including Gosiger, will display the latest machine tool accessories that can help optimize your productivity.

THE RIGHT MACHINE FOR THE RIGHT PRICE

THE RIGHT MACHINE FOR THE RIGHT PRICE

Machining aluminum alloys for aerospace, electronics, computers, and other applications presents a number of challenges for CNC machine shops. If you’re considering expanding your capabilities to include making aluminum alloy parts, there are a number of important factors to consider:

Machining aluminum alloys for aerospace, electronics, computers, and other applications presents a number of challenges for CNC machine shops. If you’re considering expanding your capabilities to include making aluminum alloy parts, there are a number of important factors to consider:

This video demonstrates how a Fanuc M20iB services a 5-axis Okuma machining center. The robot is mounted on a Robot Transfer Unit (RTU) that enables it to handle multiple machine tools. This clip shows how parts are loaded through a custom side door on the machine tool so operators have access to the both the front of the machine and the machine’s control panel.