Many newer cars have maintenance reminders built in that alert owners when it’s time for routine services like oil changes, which is a great convenience. Surprisingly, having this feature doesn’t keep some drivers from putting off servicing the vehicle until problems arise. True, you still must make the appointment and then either wait, or leave and arrange for someone to take you back to pick up the vehicle. However most of us realize that it’s important to protect this major investment, and that preventative maintenance is less costly and less inconvenient than dealing with a breakdown.

Many newer cars have maintenance reminders built in that alert owners when it’s time for routine services like oil changes, which is a great convenience. Surprisingly, having this feature doesn’t keep some drivers from putting off servicing the vehicle until problems arise. True, you still must make the appointment and then either wait, or leave and arrange for someone to take you back to pick up the vehicle. However most of us realize that it’s important to protect this major investment, and that preventative maintenance is less costly and less inconvenient than dealing with a breakdown.

Dayton OH – According to machine tool distributor and factory automation specialist,

Dayton OH – According to machine tool distributor and factory automation specialist,  With 2013 winding down, we’re all looking forward to the promise of another good year for manufacturing in 2014 and, although it may seem far away, we’re also looking forward to IMTS 2014. Early indications are that a record number of exhibitors and visitors will grace the halls of McCormick place next September 8 – 13. Certainly there will be exciting new technologies and sharing of information that will help everyone from the smallest CNC machine shop to the largest mega-manufacturers advance their operations. Here are a few other highlights according to information released by The Association for Manufacturing Technology (AMT).

With 2013 winding down, we’re all looking forward to the promise of another good year for manufacturing in 2014 and, although it may seem far away, we’re also looking forward to IMTS 2014. Early indications are that a record number of exhibitors and visitors will grace the halls of McCormick place next September 8 – 13. Certainly there will be exciting new technologies and sharing of information that will help everyone from the smallest CNC machine shop to the largest mega-manufacturers advance their operations. Here are a few other highlights according to information released by The Association for Manufacturing Technology (AMT). Investing in a 5-axis CNC machine can open doors to greater productivity, reduced capital investment, lower operator-cost-per-part and the opportunity to accept work from customer previously unavailable to you. How is this possible? Because simultaneous 5-axis machining provides all of these benefits:

Investing in a 5-axis CNC machine can open doors to greater productivity, reduced capital investment, lower operator-cost-per-part and the opportunity to accept work from customer previously unavailable to you. How is this possible? Because simultaneous 5-axis machining provides all of these benefits: Lean manufacturing has been around for quite a while, and many manufacturers have embraced the philosophy of continuously looking for ways to eliminate waste in their processes. However, the true meaning of Lean involves much more than automating an activity or streamlining an operation, as important as those things are. So here are 7 questions to ask yourself about your Lean program.

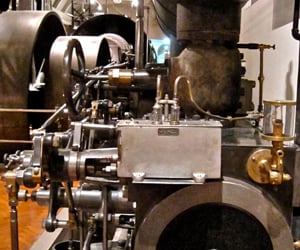

Lean manufacturing has been around for quite a while, and many manufacturers have embraced the philosophy of continuously looking for ways to eliminate waste in their processes. However, the true meaning of Lean involves much more than automating an activity or streamlining an operation, as important as those things are. So here are 7 questions to ask yourself about your Lean program. Robotic-based CNC machine tool automation is proven to reduce operator time and cost-per-part. It also enables unattended and lights-out operation, eliminates human error and improves spindle utilization. All of which greatly enhances productivity. For more on this topic, download the free white paper

Robotic-based CNC machine tool automation is proven to reduce operator time and cost-per-part. It also enables unattended and lights-out operation, eliminates human error and improves spindle utilization. All of which greatly enhances productivity. For more on this topic, download the free white paper  CNC machine tool users typically love new technologies. That’s why most have embraced the digital world through computer networks, remote monitoring and reporting, mobile devices loaded with APPs, and online transmission of CAD drawings and other important data.

CNC machine tool users typically love new technologies. That’s why most have embraced the digital world through computer networks, remote monitoring and reporting, mobile devices loaded with APPs, and online transmission of CAD drawings and other important data.