Precision of Swiss-Style Turning Machines Hinges on Construction

The distinguishing characteristic of a Swiss-style turning machine is the sliding headstock that feeds bar stock through a guide bushing. This feature enables the precise, high volume machining of many parts, especially those with small diameters. Because of the importance of accurate guide bushing positioning and spindle performance, how these components are crafted is vitally important.

Gosiger represents Nomura Swiss-style lathes because they combine modern manufacturing technology with centuries-old craftsmanship. Here are a few examples:

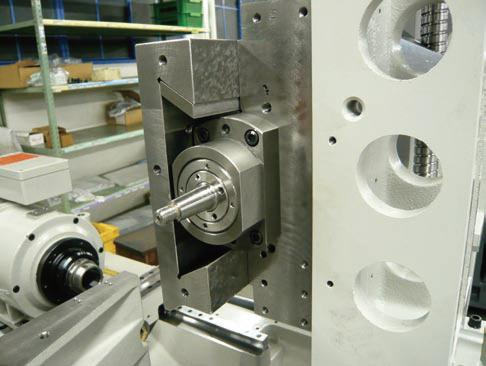

- The nature of Swiss-style machines requires a durable and true spindle. Because the spindle is hollow, the choice of material is extremely important. Nomura uses SCM415 Chrome Molybdenum steel for its spindles. When precisely machined, the outside of the spindle is then heat treated for durability, while the inside is conditioned to a different degree of hardness. This proprietary process enables the spindle to maintain greater strength, precision and stability.

- Vibration is the enemy of precision cutting and also impacts tool wear. To maintain the stability of the sliding headstock, Nomura employs a unique guiding system design. This dovetail construction, sliding on a thin film of oil, enables the headstock to move smoothly and accurately, while sliding mechanism absorbs much of the harmonic vibrations caused by high-speed rotation of bar stock.

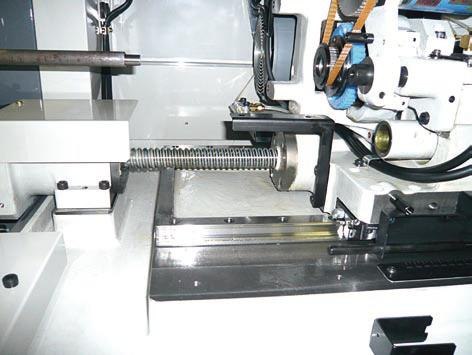

- To achieve the degree of surface smoothness and flatness required for stable, vibration-free operation of the guiding surfaces, Nomura relies on a 200-year old hand scraping technique called Kisage. In this process, an expert with ten years invested in acquiring this skill, uses a variety of hand tools for rough, moderate and fine finishing. The result is an ultra-precise surface with sub-micron unevenness of less than 0.0001mm. The hand scraping takes a full day per machine, and although power scraping devices could accelerate the process, it can’t duplicate the degree of flatness achieved through Kisage.

- In addition to this rigorous construction process, Nomura uses larger-than average ball screws in each axis to convey power from the motor to the headstock. This combination of heavy-duty ball screws, proprietary heat-treating of the inside and outside of the spindle, the dovetail construction of the guiding system and the application of Kisage hand scraping techniques reduces vibration, improves cutting efficiency and precision, reduces tool wear and improves product quality.

- With all Swiss-style turning machines, accurate tool presetting is critical. That’s why Nomura developed an outboard tool presetter with a tool holder and 10X microscope. This unit simplifies accurate tool setting by (1) adjusting the cutting edge in the X & Y axial direction and (2) Adjusting the blade end for the Z-axis. The result is faster, more accurate tool setting than with typical Swiss-style lathes.

In addition to these highlights, there are a number of other factors to consider when choosing a Swiss-style turning machine. The experts at Gosiger, Inc. have the knowledge and experience to help you determine the right machine tools for your manufacturing ope