Bill Goodman, President of Inland Tool & Manufacturing, Inc., saw little opportunity to benefit from factory automation. “Along with our production stamping and light assembly businesses, we produce individual prototypes and tooling, or small batches of parts in our machining operations,” he explains, “So automation really hasn’t been much of an issue.”

Bill Goodman, President of Inland Tool & Manufacturing, Inc., saw little opportunity to benefit from factory automation. “Along with our production stamping and light assembly businesses, we produce individual prototypes and tooling, or small batches of parts in our machining operations,” he explains, “So automation really hasn’t been much of an issue.”

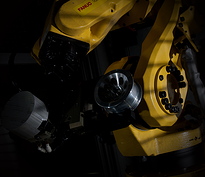

Things changed, however, when Inland began making production runs of a family of parts for heavy-duty cable clamps used on slings attached to derricks for loading and unloading freight, and in the lumber industry. That’s when they decided to investigate how applying factory automation to this repetitive process might save them time and reduce labor costs. They chose an Okuma Captain L-370MWBB CNC lathe as the centerpiece and worked with Gosiger Factory Automation to create a cell that integrated an LNS Quick Load Servo 80 bar feeder, inbound and outbound parts conveyors, and a Fanuc M-6iB/6S robot to handle parts.

Robotic-based CNC machine tool automation is proven to reduce operator time and cost-per-part. It also enables unattended and lights-out operation, eliminates human error and improves spindle utilization. All of which greatly enhances productivity. For more on this topic, download the free white paper

Robotic-based CNC machine tool automation is proven to reduce operator time and cost-per-part. It also enables unattended and lights-out operation, eliminates human error and improves spindle utilization. All of which greatly enhances productivity. For more on this topic, download the free white paper  It seems like the pressure on manufacturers just keeps building. The competition is coming at you from down the street, around the corner and across the water. Costs for qualified operators (if you can find them), health care, materials and energy keep rising, while customers demand higher quality, lower prices and faster delivery.

It seems like the pressure on manufacturers just keeps building. The competition is coming at you from down the street, around the corner and across the water. Costs for qualified operators (if you can find them), health care, materials and energy keep rising, while customers demand higher quality, lower prices and faster delivery.