Gosiger personnel will be on hand in Okuma America’s IMTS booth 2018 (338500, South Hall) throughout the Show to introduce visitors to the latest CNC machining technologies including:

Gosiger personnel will be on hand in Okuma America’s IMTS booth 2018 (338500, South Hall) throughout the Show to introduce visitors to the latest CNC machining technologies including:

The many benefits of 5-axis machining include:

The many benefits of 5-axis machining include:

Gosiger opened its new West Coast headquarters earlier this year, showing off the new 17,500 square foot facility during an open house event in May. Customers toured the new space, participated in technical seminars, and watched demonstrations of the latest CNC machining techniques.

On January 9, 2017 Gosiger moved its West Coast headquarters from Fullerton, CA to a new, 17,500 square foot building in Cypress, CA, The new facility is approximately twice the size of the previous space with an expanded showroom, training area and replacement parts inventory.

On the Gosiger web site you’ll find many resources that can help you meet a number of manufacturing challenges. Among these are customer success stories that all have a common theme: The customer was faced with a specific need that required something more than an off-the-shelf product. They needed a partner with deep and broad machine tool and engineering experience to determine the best way to achieve their desired outcomes – both immediate and for the future.

From time-to-time a company may rethink how it takes its products to market. For machine tool OEMs the question is: Should we sell directly to the end user, or work through a distributor? Considering the complexities of selling, installing, training and servicing today’s sophisticated machine tools, it makes good sense for OEMs to form a partnership with an experienced, stable machine tool distributor.

THE RIGHT MACHINE FOR THE RIGHT PRICE

THE RIGHT MACHINE FOR THE RIGHT PRICE

Dayton OH – According to machine tool distributor and factory automation specialist, Gosiger Inc., new software and machine control technologies enable manufacturers to integrate dimensional part inspection within a robotically automated CNC machining cell.

Dayton OH – According to machine tool distributor and factory automation specialist, Gosiger Inc., new software and machine control technologies enable manufacturers to integrate dimensional part inspection within a robotically automated CNC machining cell.

Despite improvements in the overall economy, unemployment in the U.S. remains higher than desirable. Even so there are CNC machine shops that can’t find qualified candidates for available jobs. One reason is that experienced machine operators who are capable of working with today’s advanced manufacturing equipment are hard to find. Another is that many young people have a misconception of what working in a modern manufacturing facility is like. Worse yet, those who have an interest may not have the opportunity to gain experience with today’s sophisticated CNC machine tools and, therefore, are less desirable new hires.

Despite improvements in the overall economy, unemployment in the U.S. remains higher than desirable. Even so there are CNC machine shops that can’t find qualified candidates for available jobs. One reason is that experienced machine operators who are capable of working with today’s advanced manufacturing equipment are hard to find. Another is that many young people have a misconception of what working in a modern manufacturing facility is like. Worse yet, those who have an interest may not have the opportunity to gain experience with today’s sophisticated CNC machine tools and, therefore, are less desirable new hires.

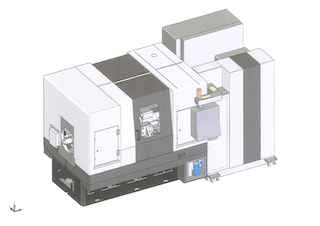

Dayton, OH – Machine Tool Distributor and Automation Systems Integrator Gosiger, Inc. has developed a new product to enable Okuma CNC machine users to seamlessly integrate a variety of peripheral devices such as bar feeders, high-pressure coolant systems, hydraulically activated fixtures and steady rests through one interface to the machine’s OSP 200 and above control.

Dayton, OH – Machine Tool Distributor and Automation Systems Integrator Gosiger, Inc. has developed a new product to enable Okuma CNC machine users to seamlessly integrate a variety of peripheral devices such as bar feeders, high-pressure coolant systems, hydraulically activated fixtures and steady rests through one interface to the machine’s OSP 200 and above control.