High precision machining and high volume production don’t always go hand-in-hand. That’s why Swiss watch makers developed sliding headstock turning machines that achieve both goals.

High precision machining and high volume production don’t always go hand-in-hand. That’s why Swiss watch makers developed sliding headstock turning machines that achieve both goals.

Swiss-style sliding headstock CNC machine tools are ideal for high volume output, provided they have the necessary rigidity and accuracy. In this video you’ll see how a Nomura NN20UB8 turning machine equipped with a Quick Load Servo bar loader makes long shafts from blanks with no operator intervention.

.jpg) Gosiger High Volume Division provides unique solutions for manufacturers who want to increase throughput, reduce cost-per-part and improve time-to-market. In IMTS booth S-9266 visitors can see these products for themselves and discuss their specific applications with Gosiger technical experts. Product lines represented include:

Gosiger High Volume Division provides unique solutions for manufacturers who want to increase throughput, reduce cost-per-part and improve time-to-market. In IMTS booth S-9266 visitors can see these products for themselves and discuss their specific applications with Gosiger technical experts. Product lines represented include:

According to Mark Walker of Gosiger High Volume.

According to Gosiger’s David Cogswell, the common theme expressed by attendees of the 2013 Medical Design & Manufacturing Show West was a desire to improve or expand their manufacturing capabilities. “The people I spoke with were company owners, manufacturing engineers and other production people looking for better ways to make their products, and to expand their businesses.” This, of course, bodes well for both the manufacturing sector and the overall economy.

According to Gosiger’s David Cogswell, the common theme expressed by attendees of the 2013 Medical Design & Manufacturing Show West was a desire to improve or expand their manufacturing capabilities. “The people I spoke with were company owners, manufacturing engineers and other production people looking for better ways to make their products, and to expand their businesses.” This, of course, bodes well for both the manufacturing sector and the overall economy.

BTB Transfer, Bovezzo Italy, demonstrates how high output / quick changeover metal cast machining solutions can go hand in hand without sacrificing a manufacturer’s future flexibility. Transfer machining solutions are known for fast cycle times, small footprints, high accuracy and reduced labor costs. On the downside, a transfer solution can also mean a loss of flexibility and long changeovers, especially when a solution needs to address the many part numbers contained in a single or multiple family of parts. BTB’s new M10 transfer machine takes aim with a serious solution. The platform delivers 5 axis (3 axis machining + 2 axis clamping) horizontal and vertical machining capability at 5 of the machines’ 6 stations. Additionally, each horizontal and vertical station utilizes a 6 tool, tool changer for a total of 60 available tools. The machine is a viable alternative to multiple, stand-alone machining centers for the mid- high volume manufacturer. BTB Transfer is sold and serviced exclusively in North America by Gosiger High Volume, Dayton OH.

BTB Transfer, Bovezzo Italy, demonstrates how high output / quick changeover metal cast machining solutions can go hand in hand without sacrificing a manufacturer’s future flexibility. Transfer machining solutions are known for fast cycle times, small footprints, high accuracy and reduced labor costs. On the downside, a transfer solution can also mean a loss of flexibility and long changeovers, especially when a solution needs to address the many part numbers contained in a single or multiple family of parts. BTB’s new M10 transfer machine takes aim with a serious solution. The platform delivers 5 axis (3 axis machining + 2 axis clamping) horizontal and vertical machining capability at 5 of the machines’ 6 stations. Additionally, each horizontal and vertical station utilizes a 6 tool, tool changer for a total of 60 available tools. The machine is a viable alternative to multiple, stand-alone machining centers for the mid- high volume manufacturer. BTB Transfer is sold and serviced exclusively in North America by Gosiger High Volume, Dayton OH.

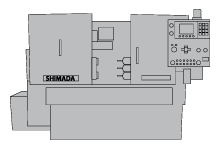

DAYTON OH – CNC machine tool distributor and factory automation specialist Gosiger, Inc. announces that its High Volume Division is now the exclusive distributor of Shimada 6- and 8-spindle lathes in North America. In this role Gosiger will provide application engineering, technical service, parts and customer support.

DAYTON OH – CNC machine tool distributor and factory automation specialist Gosiger, Inc. announces that its High Volume Division is now the exclusive distributor of Shimada 6- and 8-spindle lathes in North America. In this role Gosiger will provide application engineering, technical service, parts and customer support.

Gosiger’s High Volume Division provides unique products for out-of-the-ordinary CNC machining applications:

Gosiger’s High Volume Division provides unique products for out-of-the-ordinary CNC machining applications:

DAYTON OH – CNC machine dealer and factory automation integrator, Gosiger, Inc. will display several new high-volume manufacturing products and examples of robotic-based automation systems in IMTS 2012 booth S-9266.

Representative products from the high-volume manufacturing products line include: